| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HUIXUAN |

| Model Number : | 80T |

| Certification : | ISO9000, TÜV, BV, LR, ABS,RINA, GL, KR, DNV, NK, PED |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 500 pc/month |

| Delivery Time : | 20-50 days |

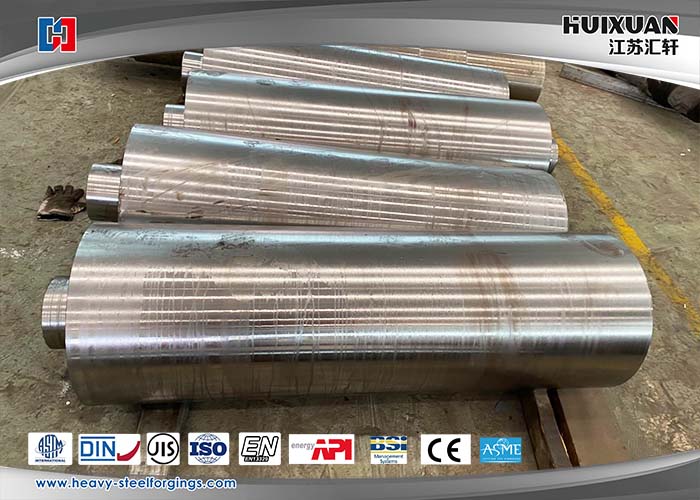

Carbon Steel Alloy Steel Drive Shaft Forgings 45# 1045 ASTM4140 4340 18CrNiMo6

Products:

Transmission system shaft forgings, alloy steel shaft, QT shaft and high quality shaft.sugarcane machinery shaft

Products reference:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Custom properties

| C | Si | Mn | P | S | Cr | Ni | Mo |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.60-0.90 | ≤0.035 | ≤0.040 | 0.80-1.10 | -- | 0.15-0.25 |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | -- | 0.15-0.25 |

| 18CrNiMo7-6 | 0.15-0.21 | 0.17-0.35 | 0.50-0.90 | ≤0.025 | ≤0.025 | 1.50-1.80 | 1.40-1.70 | 0.25-0.35 |

| 4340 | 0.38-0.43 | 0.15-0.35 | 0.60-0.80 | ≤0.035 | ≤0.040 | 0.70-0.90 | 1.65-2.00 | 0.20-0.30 |

| 34CrNiMo6 | ≤0.34 | 0.25-0.30 | ≤0.5 | ≤0.035 | ≤0.040 | ≤1.5 | ≤1.55 | ≤0.2 |

| 1045 | 0.43-0.50 | 0.60-0.90 | ≤0.040 | ≤0.050 |

|

|

|

|

|

|

|

|

4140 | Ø10 | 740~1000 | 450~850 | ≥12 | ≥25 | ≥40 | ≤250HBS |

4130 | Ø10 | ≥930 | ≥735 | ≥12 | ≥50 | ≥71 | ≤229HBS |

18CrNiMo7-6 | Ø15 | ≥980 | ≥785 | ≥9 | ≥40 | ≥47 | ≤269HBS |

4340 | Ø15 | ≥980 | ≥835 | ≥12 | ≥55 | ≥78 | ≤179HBS |

Process procedure:

Forging process flow quality control: Raw material steel ingot into

warehouse(test the chemical content)Cutting Heating(Furnace

temperture test) Heat treatment after forging(Furnace temperture

test) Discharge the furnace(blank inspection) Machining

Inspection(UT,MT,Visal diamention, hardness)QTInspection(UT,

mechanical properties, hardness, grain size)Finish machining

Inspection (dimension) Packing and Marking(steel stamp, mark)

Storage Shipment

Commerce clause

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keywords

Various of shafts made of alloy steel, carbon steel, stainless

steel that mainly used for transmission, mining equipment and so on

have good mechanical properties. Drive shaft is composed by axel

tube, flexible sleeve and cardan to joint or assemble the fitting

parts, makes the items movable or rotation. Its usually made of

light alloy steel tube that have good enduring twist.

Advantage

|