| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HUIXUAN |

| Model Number : | Q345D,50Mn,42CrMo4,17CrNiMo6 |

| Certification : | ASTM,ASME,DIN,JIS,ISO,BS,API,EN |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 3000-5000Ton/month |

| Delivery Time : | 15-50Days |

| MOQ : | 1PC |

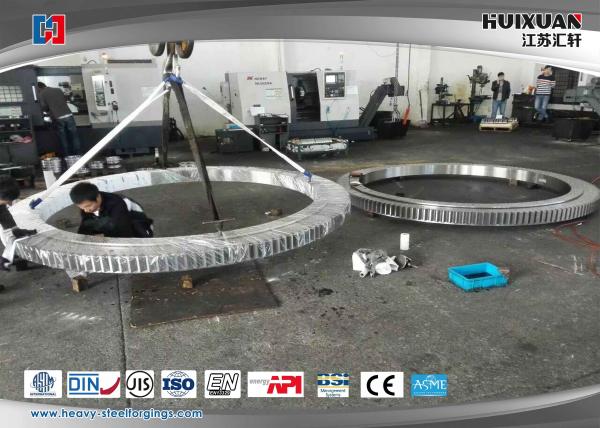

Industrial Alloy Steel Forgings Excavator Slewing Bearing ASME Standard

Products:

Excavator parts,slewing bearing of excavator,tower crane parts,slewing bearing of tower crane.

Slewing bearing is after machining process,widely used for industrial machinery,excavator,construction tower cane,mining equipment,cement machinery.

Products reference:

| Material | Q345D,50Mn,42CrMo4,17CrNiMo6 |

| Max dia | 5000MM |

| Application | Slewing bearing is used for excavator,tower crane |

| Melting process | EF+LF+VD |

| Production process | Forging+heat treatment+rough machining+roller bed harden+finish machining |

| Forging ratio | ≥5 |

| Applicable standard | ASTM,ASME,DIN,JIS,ISO,BS,API,EN ,DIN |

| Executive standard | JB/GB/EN/DIN/JIS/ASME/ASTM/ISO |

| Certification authority | ISO,BV,SGS, IST, UL,CTI |

| Delivery term | Rough machining(N+T);finish machining(Q+T) |

| Test equipment | Spectrograph,UT device,tensile and compact test machine,metalloscope,outside micrometer,bore dial indicator,hardness test machine |

| Service | Our service included the forging, process, heat treatment, finish machining, package, local logistics, customers clearance and maritime transport. We took the customer’s requirements as the principal thing, and pay attention on the products quality. |

Custom properties

Material elements | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| 42CrMo4 | 0.38-0.43 | 0.15-0.35 | 0.60-0.90 | ≤0.035 | ≤0.040 | 0.80-1.10 | -- | 0.15-0.25 | - |

| Q345D | 0.13-0.20 | 0.17-0.37 | 1.20-1.60 | ≤0.030 | ≤0.030 | ≤0.30 | ≤0.30 | -- | |

| 17CrNiMo6 | 0.15-0.21 | 0.17-0.35 | 0.50-0.90 | ≤0.025 | ≤0.025 | 1.50-1.80 | 1.40-1.70 | 0.25-0.35 | |

| 50Mn | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.30 | -- | 0.48-0.56 |

Mechanical property | Dia.(mm) | TS/Rm(Mpa) | YS/Rp0.2(Mpa) | EL/A5(%) | RA/Z(%) | Type Of notch | Impact energy | HBW |

| 42CrMo4 | Ø15 | 740~1000 | 450~850 | ≥12 | ≥25 | V | ≥40 | ≤250HBS |

| Q345D | Ø10 | 470-630 | ≥345 | ≥21 | -- | V | -20℃≥27 | == |

| 18CrNiMo6 | Ø15 | ≥980 | ≥785 | ≥9 | ≥40 | V | ≥47 | ≤269HBS |

| 50Mn | Ø25 | ≥645 | ≥390 | ≥13 | ≥40 | V | ≥31 | ≤255HBS |

Commerce clause

| Max weight | 5T |

| MOQ | 1PC |

| Delivery time | 15-50 days |

| Package | Plywood case,Wooden pallet,Steel frame |

| Delivery term | FOB;CIF;CFR;DDU; |

| Payment term | T/T,LC |

| Type of shipping | By ocean,air |

Process procedure:

Forging process flow quality control:

Why choose HUIXUAN?

|